Table of Contents

Are Passive Houses cost-effective?

Varying opinions about the Passive House abound, not only on the internet. It is still claimed by some that Passive Houses are not affordable. And others claim that a profit of over “200,000 Euro” can be made with a single-family Passive House.

Anticipating the results of a serious analysis, it suffices to say that none of these statements are correct. Under the present conditions in Germany and Austria, the construction of Passive Houses is profitable if they are built and designed competently. But quick profits should not be expected. The Passive House is more stable, more secure and more worthwhile than the alternative. Whoever wants “easy money” should try something else (…of course, the risk of losing a lot of money will also be greater).

An analysis using the example of a single-family house

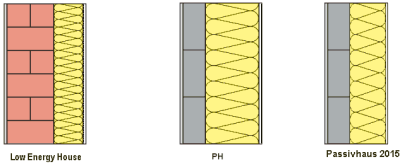

The house in Fig. 1 is a conventional detached house with a floor space of 149 m². It's not a Passive House – but it would be quite easy to build it as a Passive House. For that, the following details would have to be improved:

- The external wall insulation should be increased to 300 mm and the brickwork should be reduced to 115 mm lime sandstone; this way the external wall will only be slightly thicker than it was before (about 25 mm) (see Fig. 2).{ Remark from 2015: Because of the improvements in Passive House windows, a new built passive house now would only need some 200 mm of insulation (0.032 W/(mK)); the external wall will therefor be only 370 mm thick and thus thinner than the original one}

- In the roof, the insulation under the rafters and on the top ceiling should be increased from 100 to 225 mm each; between the rafters and in the ceiling it should remain 140 mm as before, with a thermal conductivity of 0.035 W/(mK).{Remark 2015: The roof will have to met some 0.12 W/(m²K), which can be achieved in a lot of different ways and what will not add costs if done in a propper way}

- On the floor slab a total of 250 mm instead of 150 mm of PS insulation boards with a heat conductivity 0.035 W/(mK) should be used.{ Now, 2015, the 150 mm of the original Low-Energy-Home solution will be sufficient; no extra costs}

The existing house was also a mostly thermal bridge free construction; except for the increase in insulation thicknesses and the installation of the windows outside in front of the brickwork, no changes are required. In place of the wooden beam ceiling on the ground floor used in the original construction, it is supposed that a concrete ceiling is used for the Passive House variation;

- this will have a considerably smaller build-up height and is even cheaper;

- this way it will be possible to gain more room height in the upper floor in spite of the slightly thicker insulation in the roof while the external height of the house remains the same.

- the living area may slightly increase due to this, but we will not include the increased living space (a marginal 1 m²) in the calculation, so that the comparison does not become even more complicated due to a change in the reference areas.1).

The savings due to the simpler ceiling construction will not be taken into account either.

|

| Fig. 3: Floor plan of the single family Passive House (ground floor). Due to intelligent planning the ventilation ducts are very short. |

All external walls are evenly plastered, the roof structures contain airtight membranes, which are plastered up in the knee wall area. Based on existing experience, airtightness corresponding to n50=0.4 h-1 can be achieved with this approach. There are no extra costs associated with this – in fact, costs are reduced because increased airtightness prevents building damage, the repair of which is much more expensive than the one-off investment in a high quality, airtight external envelope; besides that, there is the additional benefit of health living conditions, which can't be calculated in financial terms.

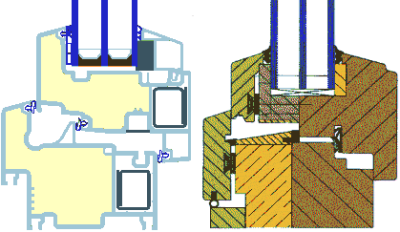

- Low-e triple-glazing in Passive House suitable frames should be installed in place of the original double-glazed windows (Fig.5). The window U-value will be reduced to 0.75 W/(m²K) on average, including the installation thermal bridge. The average g-value of the glazing is 0.54. { Remark from 2011: This year, new products with even better windows come to the market. The U-values can be reduced down to 0,65 W/(m²K), the g-values increased to 0,65. Even more important: The new windows have much smaller frame areas, thus increasing the light and the solar energy gains. All this together makes it much easier to achieve the Passive House Standard and allows a reduction of the thickness, as mentioned discussing the exterior walls } .

- A modern Passive House suitable ventilation system with an effective heat recovery of 92% should be installed. The concept for air distribution has been redesigned (see Fig. 3 and 4).

|

| Fig. 5: Passive House suitable windows. Highly insulating windows are indispensable in a Passive House. Besides saving energy, such windows have many additional advantages, see this page: Passive House - Windows. |

With the improvement of the details as described above, the Passive House Standard has already been achieved. The existing heating (boiler in storage room) can be retained. Nevertheless, even greater efficiency is possible: the ventilation can be combined with a compact heat pump unit (already drawn in H-W room). This would eliminate the need for the oil tank, the chimney and the boiler. The heat distribution pipes and radiators can also be dispensed with, or at least they can be minimised; the compact unit can provide heat directly to the supply air; an extra heating element would be needed only in the bathroom on the second floor, so that the temperature can be increased quickly.

What will all this cost?

The improved thermal insulation necessitates more insulation materials and its application, better windows require an extra coated glass pane and an insulated frame, the heat recovery system will need ductwork:

- Additional costs for thermal insulation in wall, roof and floor slab: € 4800 { in the 2015 case reduced by 500 € }

- Additional investment for Passive House windows: € 5400 { That was until 2010; but now, windows with even better performance are available on the market - and these cost less, some 1600 € will be covering all difference costs to conventional windows }

- Additional costs for ventilation with heat recovery: € 5200 So far, even in 2015, this did not change much. But: now developments are in the pipe to reduce these costs significantly

- Less costs for smaller oil tank, boiler; radiators and distribution pipes are no longer required, post-heater coils instead: - € 1400 (the additional useable area is not taken into account)

⇒ Sum of additional capital outlay: € 14000

in 2015, it's reduced already to € 9500 and still getting less expensive

To be on the safe side, we will assume that an additional total investment of € 15000 was necessary in 2010, and in 2015 this is already reduced to less than 10000 €. This was about 8% of the total average construction costs for such a house in Germany - and it's less than 5% alreday in 2015 with still existing potentials to lower the extra investment even more.

Financing the house

We will assume that there is no more capital available and the additional investment must be financed through a higher mortgage loan. At an interest rate of 4.7% and 1.6% repayment rate, this means an additional annual interest repayment of € 945.

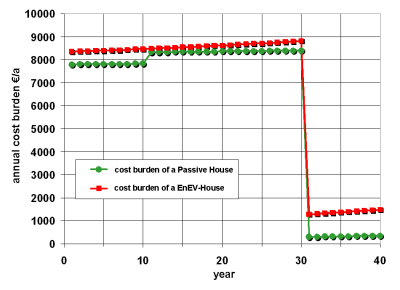

However, for the construction of a Passive House, the house builder can apply for the KfW’s (Development Loan Corporation) “Energy-efficient construction” ESH50/Passivhaus low-interest loan, which has a 100% pay-out and interest rate of only 2.10% (last updated at the end of April 2006). € 50000 are paid per accommodation unit, in this case for a single-family house. There is a lower annual cost burden of around € 880 in the first few years due to the lower interest rate. In this way, the annual cost burden due to the additional investments is almost completely compensated by the savings in interest for the example being dealt with here. What the situation will be like later on, is shown in Fig. 6.

It gets even better: instead of using about 13300 kWh fuel oil or natural gas, the Passive House only requires approximately 2290 kWh fuel for heating and 350 kWh electricity for the ventilation system. This saves € 715 per year - at 2009 fuel costs (which was 65 Cent per litre of heating oil; 2011 the savings are already € 825), while electricity for the ventilation system costs about € 65 per year.

| Investments and savings for a Passive House (149 m²) - Comparison for the first few years - Additional investment* compared with a standard house: € 15 000 additional repayment in the first year (bank): + € 945/year Reduced cost burden due to low interest loan (first year): - € 880/Jahr (KfW ESH40/Passivhaus) With energy savings of 11000 kWh/a for heating: Savings in heating energy costs with 65 cents/litre heating oil: - € 715/year Additional costs for electricity for ventilation with 18 cents/kWh: + € 65/year Result: reduction of the cost burden in the first few years: € 585/year * Beispiel: based on prior to 2010 experience, the investment can now be lower. Notice concerning methodology see: 2) |

Is it worthwhile?

In contrast with a “normal house“, the cost burden is considerably less for the construction of a Passive House, even if energy costs do not increase in the future. The Passive House Standard is therefore economically attractive – even though the profits are not as enormously high as sometimes promised. But the house builder does benefit from a few more things.

Enjoyment of life!

Energy consumption is so low in the Passive House that the occupants no longer have to worry about increasing energy prices. The house is practically independent of imported energy sources - it can even be supplied with renewable energy alone if a compact heat pump unit is installed and a green electricity provider is chosen (or if shares in a wind-energy generator are bought or wood pellet heating is used or …).

But there are even more benefits: there are no mildewed walls, no cold draughts, no cold feet in the Passive House. Instead, there is always fresh air and less indoor air pollution in the house.

As Robert Hastings stated at the 8th International Passive House Conference: ”Passive Houses should be optimised for minimum environmental impact and maximum enjoyment of life”.

The occupants can also profit from the reduced environmental impact: the consequences of climate change affect everyone; in Passive Houses, climate-damaging emissions are reduced by a factor of 4 when compared with “normal” new buildings. The more people decide in favour of energy-efficient construction of new buildings or renovation of existing buildings, the more effective the contribution to environmental protection will be.

These are the individual advantages to be gained – but doesn’t the Passive House builder also benefit if services are provided regionally, and not through energy commodities imported from unstable parts of the world? If a Passive House, like the one shown previously, currently costs € 14000 “more” than an ordinary new building, then 75 % of this € 14000 is rendered as trades services. The remaining 25 % stems mainly from European value creation. This preserves and creates employment and can even be “profitable”. We need not discuss the costs that can be saved if we don’t have to deal with international tensions, there is enough of that in the newspapers every day. This too contributes to the enjoyment of life, because “securing energy resources” doesn't only cost money.

Saving costs with energy efficiency – in the long term

Saving energy is what mainly contributes to relieving the burden in the long term – fortunately, because depending on development loans alone could lead to a higher cost burden after the expiry of the fixed interest rate. Therefore, it is advisable to use building incentives only for demonstrably energy-efficient measures. For example, for improving the thermal insulation, windows and the ventilation system with heat recovery as specified above. That these measures really do save energy in practice, has actually been proven through measurements (see for example: Energy efficiency of the Passive House Standard: Expectations confirmed by measurements in practice).

The following table and Fig. 6 show the average result of the financial mathematical calculation over a period of 30 years. There is another benefit, as Fig. 6 shows:

Even after 30 years one can continue to profit from reduced energy costs, because the inactive components of the Passive House continue to function as long as the house stands.

Table showing the annual average costs over a period of 30 years based on the financial mathematical calculation method:

| Investment and savings for a Passive House (149 m²) - financial mathematical calculation over a period of 30 years nominally - Additional investment *) compared with a standard house € 15000 Average additional repayment to the bank): + € 945/year Average reduced cost burden due to low interest loan over 30 years: - € 626/year (KfW ESH40/Passivhaus) With energy savings for heating of 11000 kWh/a: Average energy savings for heating over 30 years: - € 822/year (nominal price increase 1.6 %/a) average additional costs of electricity for ventilation: + € 71/year Result: Reduction of the annual cost burden: € 432/year * Example: based on experience, the investment can also be lower. |

Boundary conditions:

KfW credit incentive ESH40/Passivhaus (updated end of April 2006). Interest (nominal) 2.1 % p.a. 100% payment, 30 year duration, here:

- without repayment period. First few years. Cost-based usage duration: 30 years,

- interest rate for calculation 4.7 % p.a. (mortgage loans, nominal, effective)

- fuel price: 6.5 cents/kWh(actual 2006),

- electricity 18 cents/kWh (actual 2006),

- energy price increase equal to inflation rate of 1.6% p.a. (nominal).

Remark, update 2015:

Fuel prices have been up (more than 9 cents/kWh) and down (now again in the same range as 2006). These hefty short term changes are consistent with our evaluation in Cost-effectiveness analysis. These short term changes, however, level each other in the life cycle of the building. Using 6.5 cents/kWh for this whole period will underestimate the energy costs. These 6.5 cents have been used in this analysis - average energy costs in the future will not be lower than these.

Capital costs have been falling all the time - interest rates are really low (2015), in the range of 2%/yr for a mortage loan (nominal). The internal interest rates used in the analysis here are higher - thus overestimating the capital costs of the energy saving measures. Also, the investment costs of these measures have been reduced with better and less expensive solutions getting available.

Conclusion: The economic conditions for improvement of insulation and other energy conservation measures are even better now than these have been in 2006. The analysis documented here is on the save side.

Method: The actual cash values of all cash flows are determined nominally and converted into constant annuity values over 30 years. The components used have an expected usage duration of much more than 30 years (apart from worn out parts which are easily replaceable and also exist in conventional buildings). Maintenance costs remain unchanged.

Remark about possible changes in the boundary conditions:

This page was last updated at the end of April 2006. Prices for energy, interest rates and the requirements for incentives may change very quickly. However, such changes only have a small influence on the core statement (“yellow table”) Why?

- The economic viability of building measures that are taken is determined not so much by the current market as it is by the average economical constraints for the duration of usage of a building (which is more than 30 years).

- “Much can happen” during this period. But: Today it is possible for the building constructor to have the interest rate conditions fixed at a comparatively low level for the next twenty or thirty years. It is rather unlikely that energy will become cheaper on average in the next few decades than it is now. The most important parameters are relatively certain, even if current fluctuations occur from time to time which give a different impression.

- Regarding the conditions for funding by the KfW, according to the Development Corporation, it intends to keep the equivalent value of the funding conditions at the same level (difference to the market rate). This means that this boundary condition will also remain constant.

- The (nominal) market interest rate in turn is strongly influenced by the inflation rate. Due to this fact, the core statement of the “yellow table” remains applicable, even if the values change nominally. All values cannot be predicted to “exactly within a few Euros”. However, the risk is highest for owners who build houses with high energy consumption.

Remark about the boundary conditions in 2015:

All of the above is still true - although boundary conditions have changed. And these conditions changed in the direction of:

- Even higher energy prices; future prices of energy are agreed now to be in the range of 8 Cent/kWh (end use heating energy), which is more than the price we used for the comparison above.

- Even lower real interest rates. That is an effect of a lot of capital being available on the market - and the frustration resulting from the bubbles in the past. This is not going to change soon: so 2% real interest rate is more probable to be the future boundary condition.

But, what changed much more, are the extra investment costs of building a passive house now, in 2015: Triple pane glazings do now have already more than 70% market penetration and have dropped in price significantly. Also the Passive house windows are much less expensive since 2014 - and the same will become true for the ventilation systems. So, it's no longer 14000 €, it's less than 9500 € you need in addition to build a well working passive house (140 m²). And that difference changes the picture in a dramatic way (see figure 7): In 2015 building a new residential building, and not building a passive house - that is just foolish from an economic point of view.

See also

Cost-effectiveness analysis

Superior thermal protection is affordable

Economic feasibility of Passive House retrofits ![]()

It is better to keep the reference areas the same. Here, we have actually increased the area a little, but without taking it into account.

Here we have applied the established annuity method used for such economic feasibility calculations. Cash flows which occur at various points in time are converted to constant annual payments (like the effective annual interest + repayment for a loan). The consideration period has been set as 30 years; the building components used will function at least this long. This method is also used in the VDI 2067 guidelines, for example.

The results of this economic feasibility calculation concur with the actual cash value and internal rate of return method, if the same conditions are applied for calculations. All the methods mentioned are dynamic methods and are suitable for the evaluation of economic viability.

The calculation of the payback period (known as the “amortisation period”) can give a completely different impression. Payback periods are unsuitable as a criterion for this purpose because improvement measures with shorter life spans appear to be more cost-effective; a payback period isn’t much use if the duration of usage is not known. A measure which “amortises” within six months can still be completely inefficient e.g. if the product breaks down after only three months.